Our Products

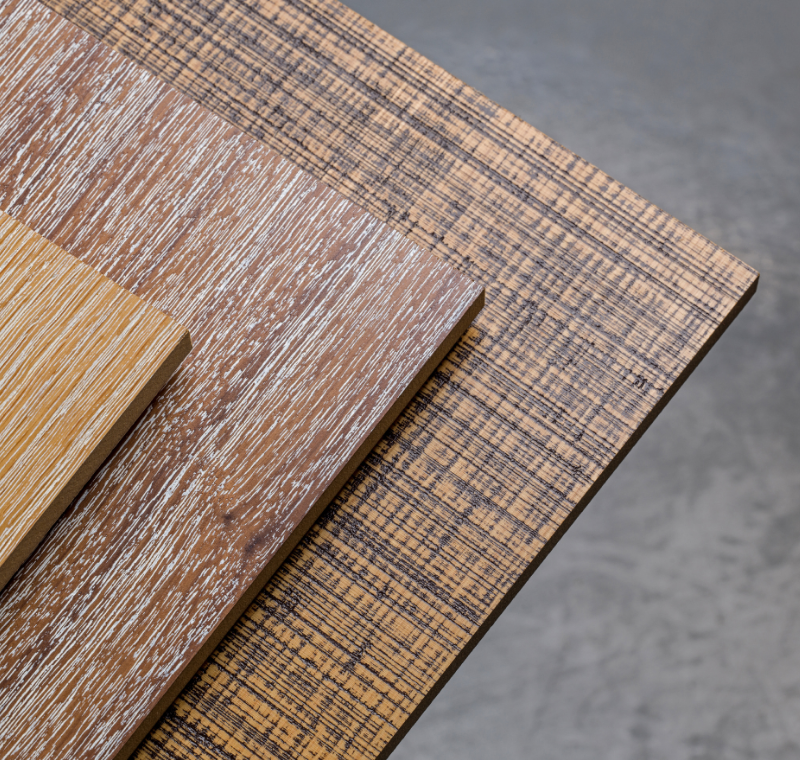

MARINE PLYWOOD

It is maintained from selected timbers bonded with high quality resorcinol Phenol Formaldehyde Resin. It is pressed under proper temperature and high pressure and treated in a vacuum pressure impregnation plant with specific preservatives as per IS 5539:1969. Modern Marine Plywood can withstand unfavorable climatic conditions, alternate drying and wetting. Moreover, it is safe against marine organisms and wood borers. Modern Marine Plywood can withstand 108 hrs. boiling at 100°C temperature without showing any signs of veneers separation/de-lamination.

Applications

Maintenance and repair of Marine and river crafts, interior of ships and liners, heat exchanger, cooling tower, public hoarding, signboards, display boards, etc., tanks for liquid chemicals, portable cabins and shelters that are exposed to severe conditions, structural applications.